As we have known, we made one unit by thousand of parts. During the assembly, time responsibility is a more important factor in automotive industries just because of the conveyor system. With the help of teamwork, we perform this activity on regular basis.

Robots work in the automotive manufacturing industry help to create jobs by restoring more manufacturing work. Robots protect humans from, repetitive, routine, and perform dangerous tasks easily. while also creating more desirable jobs, such as engineering, training, programming, troubleshooting, management, and equipment maintenance.

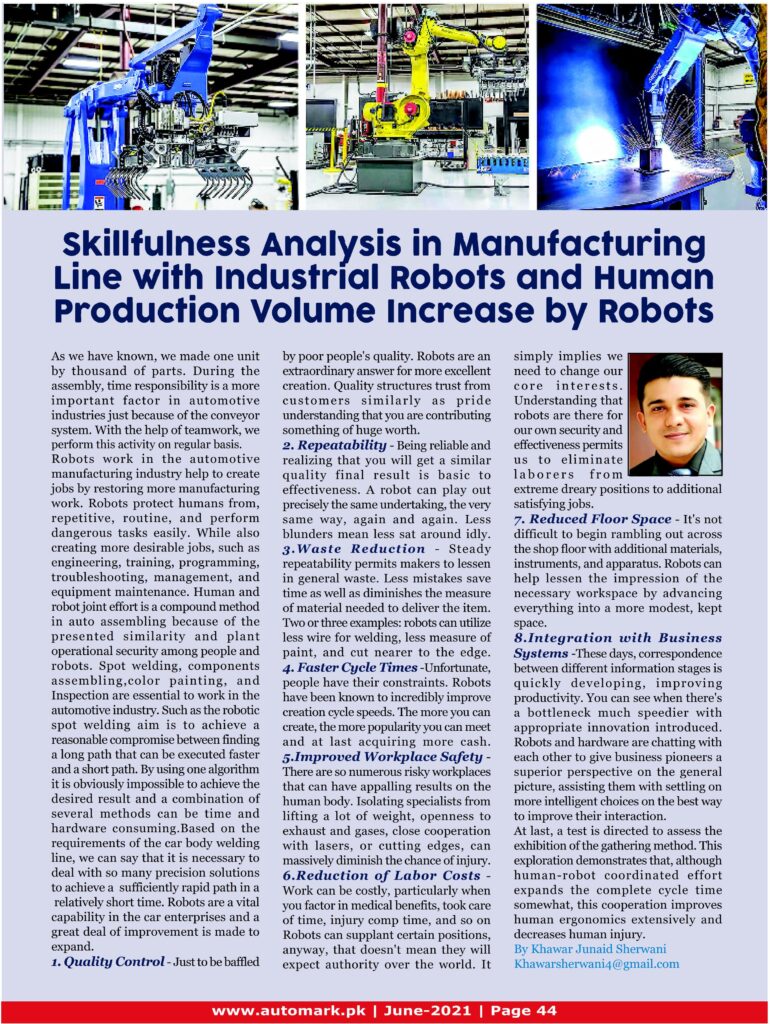

Human and robot joint effort is a compound method in auto assembling because of the presented similarity and plant operational security among people and robots. Spot welding, components assembling, color painting, and Inspection are essential to work in the automotive industry. Such as the robotic spot welding aim is to achieve a reasonable compromise between finding a long path that can be executed faster and a short path.

By using one algorithm it is obviously impossible to achieve the desired result and a combination of several methods can be time and hardware consuming. Based on the requirements of the car body welding line, we can say that it is necessary to deal with so many precision solutions to achieve a sufficiently rapid path in a relatively short time.

Robots are a vital capability in the car enterprises and a great deal of improvement is made to expand.

1. Quality Control – Just to be baffled by poor people’s quality. Robots are an extraordinary answer for more excellent creation. Quality structures trust from customers similarly as pride understanding that you are contributing something of huge worth.

2. Repeatability – Being reliable and realizing that you will get a similar quality final result is basic to effectiveness. A robot can play out precisely the same undertaking, the very same way, again and again. Less blunders mean less sat around idly.

3.Waste Reduction – Steady repeatability permits makers to lessen in general waste. Less mistakes save time as well as diminishes the measure of material needed to deliver the item. Two or three examples: robots can utilize less wire for welding, less measure of paint, and cut nearer to the edge.

4.Faster Cycle Times -Unfortunate, people have their constraints. Robots have been known to incredibly improve creation cycle speeds. The more you can create, the more popularity you can meet and at last acquiring more cash.

5. Improved Workplace Safety – There are so numerous risky workplaces that can have appalling results on the human body. Isolating specialists from lifting a lot of weight, openness to exhaust and gases, close cooperation with lasers, or cutting edges, can massively diminish the chance of injury.

6. Reduction of Labour Costs – Work can be costly, particularly when you factor in medical benefits, took care of time, injury comp time, and so on Robots can supplant certain positions, anyway, that doesn’t mean they will expect authority over the world. It simply implies we need to change our core interests. Understanding that robots are there for our own security and effectiveness permits us to eliminate laborers from extreme dreary positions to additional satisfying jobs.

7. Reduced Floor Space – It’s not difficult to begin rambling out across the shop floor with additional materials, instruments, and apparatus. Robots can help lessen the impression of the necessary workspace by advancing everything into a more modest, kept space.

8. Integration with Business Systems – These days, correspondence between different information stages is quickly developing, improving productivity. You can see when there’s a bottleneck much speedier with appropriate innovation introduced. Robots and hardware are chatting with each other to give business pioneers a superior perspective on the general picture, assisting them with settling on more intelligent choices on the best way to improve their interaction.

At last, a test is directed to assess the exhibition of the gathering method. This exploration demonstrates that, although human-robot coordinated effort expands the complete cycle time somewhat, this cooperation improves human ergonomics extensively and decreases human injury.

By Khawar Junaid Sherwani; This article has been published in printed edition of Automark Magazine June-2021.